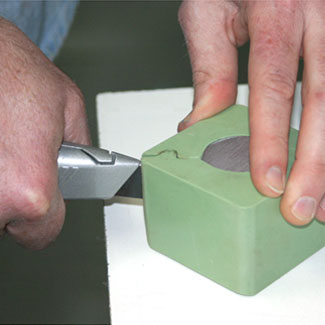

A mold knife is a specially modified utility knife with a curved blade. This knife is the secret to making molds that produce seamless castings. When cutting through a block of silicone, the curved blade cuts a rounded key into the mold. The rounded key ensures perfect registration when the mold is banded back together.

- Cutting through a block of silicone takes a certain amount of force. To prevent yourself from knocking your knuckles on the way down, hold the knife so that your hand extends over the edge of the table. Always cut the mold in the thickest area (diagonal corner) and cut straight down.

- If the blade hits the model inside, pull the blade outwards while continuing to cut downwards. Do not cut through the bottom of the mold. Stop cutting 1.25 inches from the bottom of the mold and lift the blade back towards the top to remove the knife blade.

- Usually, the mold knife blade is not strong enough to cut through the thick corner of a silicone mold. A second cut must be made with a razor knife to finish the job.

- With care, spread the partially cut portion apart. Use the tip of the razor knife to separate any uncut area. When cutting with the razor knife, always cut inwards towards the model. If you cut in the opposite direction, you are likely to cut through the ‘key’ the mold knife makes.

- Continue to cut the mold apart. This takes patience (and strong fingers). Nip at it with the blade, pulling the mold apart a little more with each cut. Do not force the mold apart by tearing it. (You are pulling the mold apart to see where you need to cut).

- Repeat the process on the opposite side of the mold.

- Remove the model.

- Use the razor knife to bridge the two cuts with one continuous cut. Do not be concerned about cutting through the detail surface of the mold. This final cut will help the mold open wider without stress. Do not cut through the bottom of the mold. Leave a small thickness at the bottom of the mold to act as a hinge.

- The mold has been successfully cut. Notice the registration groove the mold knife made. It is preferable not to cut your mold into two separate sections. A two section mold will work perfectly, however, you will have a loose mold section to keep track of for the entire life of the mold.

- A strong rubber band is used to hold the mold tightly together. If your mold is soft, the pressure of a strong band is likely to distort the shape. For soft molds, circle the entire mold in packing tape.

- Remember the ‘hinge’ cut through the bottom of the mold? The seam is invisible because the mold registered perfectly together.

- In this picture, force is applied to the banded mold to show that it does not lose registration. If the mold had been cut with a straight razor, the seam mold would slip off of itself and create a larger seam. Use a mold knife for that perfect seamless casting.